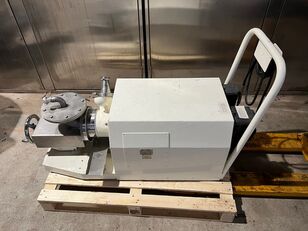

Viscotec Syringe filling system medical tool

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Germany

Germany

Marke: Viscotec

2020 Viscotec Semi-automatic syringe filling system for dronabinol

The filling system is equipped with a storage container for heating the dronabinol to 60 – 70° C and keeping the Temperature

constant during the filling process

The syringe is filled through the syringe tip and under a protective gas atmosphere (e.g. argon). No air should remain in the syringe. The filling system is suitable for the filling amounts of 265 mg

530 mg or 1060 mg with tight tolerance limits. The dosing accuracy of the Pharma Dispenser 3VHD8 (0.35ml / U) amounts 1%. The repeat accuracy is > 99%

depending on the material. Detailed material data are currently not available. The determination of the actual dosing accuracy and dosing time takes place during commissioning. The customer is taking care of the process development. The storage container has a capacity of 500 ml and withstands a pressure of 0 to +6 bar (gauge)

General information

Filling system is designed as a tabletop device

Pharma control including foot switch

o 1ph. 230V/60Hz

16A – Hygienic design

o Operating modes: Quantity control or start / stop control

menu management

o Diagnosis

parameterization and calibration function

digital monitoring

predefined

status and error messages

o Languages German / English

o Stainless steel housing (AISI 304) including touch panel

o IP65 88-264 VAC

1 Ph

16A

47-63Hz reportable lt. Art. 22 Abs 10 EG-Dual-Use VO

Suitable for GMP Processes

Suitable for filling 265 mg

530 mg or 1060 mg dronabinol in glass syringes through their

Syringe opening (Luer Cap)

The dosing accuracy of the Hygienic Dispenser 3VHD8 (0,35ml/U) amounts 1%. The

determination of the actual dosing accuracy and dosing time takes place during

commissioning

Technical Data

o Product contacted surface < = 0,8μm

o Elastomers with FDA declaration of conformity

o Parts in contact with the product can be autoclaved (max. 15min @ + 121 ° C)

o Hygienic design: easy to dismantle and clean

o Hermetically sealed process space

The filling of the syringes is carried out with a protective gas bell (protective argon

atmosphere) Alternatively

e.g. a complete enclosure under a protective atmosphere is

conceivable

The syringe is equipped with a Luer cap. If the connection is not stable a bracket for fixation

can be retrofitted

Heatable storage container for product feed

o Volume 0,5 litre

o Pressure range: 0 to +6 bar g

o Material 1.4404 / 316L

o Surface: sanded

Ra<0,8μm

o ND 50 mm

o Length approx. 600mm

o Covered with a double jacket divided into two heating zones including a guide spiral

for on-site hot water via temperature control unit

o Connections

Lid with push-in fitting for pressurization using a Ø 6mm hose

TC DN15 connections for inflow and outflow of the heating zones

TC DN15 connection for outlet

Heatable up to 60-70°C

Homogeneous temperature distribution inside the storage tank

Product pipe (bend from the storage container to the dispenser) DN 15 /

B90 double-walled for heating

Parts in contact with the product are made of stainless steel (316L) or FDA-compliant plastics

o Dispenser: 1.4404

o Storage tank 1.4404

Handling and operation are easy to understand

o The operation takes place mainly via the graphic user interface on the touch panel

Find more here

show contacts

Contact us at

show contacts